The most common X-ray machines can peer under flesh and into teeth.

Quadruple the energy and those capabilities extend to seeing through metal.

Scientists at Oak Ridge National Laboratory designed a portable device to do just that, only underwater. It’s a new invention that earned them an R&D 100 award, one of the most prestigious nods in engineering.

“For underwater X-ray imaging, all that was really available was to take a radioactive source and bring that down underwater with you,” a process Oak Ridge researcher Paul Groth said poses gamma radiation risks for divers and marine life. “Whenever you have a source like that, you’d have to also consider several hundred pounds of shielding.”

Courtesy Oak Ridge National Laboratory

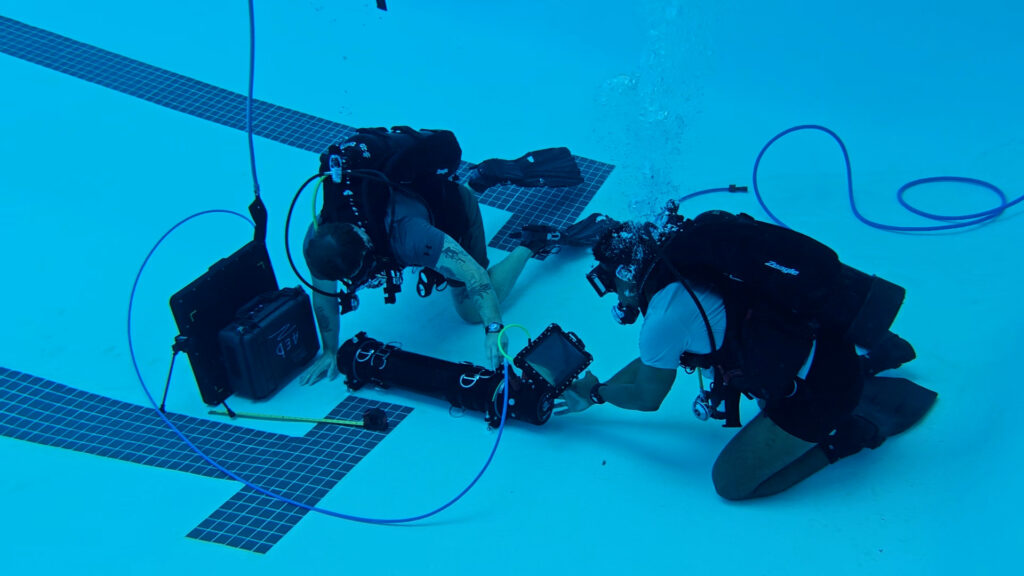

Courtesy Oak Ridge National Laboratory Oak Ridge National Laboratory engineer Jesse Davis, left, and researcher Paul Groth, right, set up an underwater X-ray imaging system on March 13, 2025.

The new device is small enough for divers to easily get imaging on a screen within minutes.

To develop an X-ray machine that’s able to look through metal pipelines or cables, Groth said they needed about four or five times more energy than a typical medical device. But since water is denser than air, there were even more challenges underwater.

Oak Ridge partnered with NOVO DR, a company that specializes in digital radiography, to enhance image processing and create software to extract low-light features from the imaging, similar to how modern phones now process data in dim scenarios. The team also partnered with the Sexton Corporation to both create a waterproof enclosure for the machine and commercialize the device.

The potential impact is high for the oil and gas industry, which manages about 20,000 miles of seafloor pipelines globally, according to the U.S. Naval Institute. With the new device, divers can examine and repair issues in real time, potentially preventing an oil spill.

“If something goes wrong, it’s a multi-million-dollar problem,” Groth said. “You really want to know what’s going on with those pipelines.”